AnshInfotech.com

TO GROW YOUR CAREER IN SAP

Wednesday, 14 December 2022

Closed MM period reopened in SAP MM

Wednesday, 30 March 2022

Open PO close with MASS t-code in SAP S/4 HANA

1. How to close the open Po’s.

Step1: -

Run the T-code- MASS and select the object

BUS2012.

|

Execute It.

You will get a new screen as per below screenshot.

And select

the highlighted line and go to “ Fields” tab and select the highlighted field

as per below screenshot.

Execute it.

Then you will get a new screen as per below screenshot.

Put the Po

no. in purchasing document field as per below screenshot.

Click on

execute icon.

Now, click

on execute icon again.

You will

get a new screen as per below screenshot.

Click on

new values indication as per below screenshot.

And click

on highlighted icon” performs changes”.

Now save

it. You will get a message as per below screenshot.

.

.

Thursday, 6 May 2021

Link Between Tax procedure & Pricing procedure ( Interview Q & A )

Question:-Where is the link between Tax procedure & Pricing procedure ?

Question:- How the taxes come into pricing procedure?

Ans:-: With regard to CIN, the only tax code which

links the Tax Procedure with Pricing Procedure.

If you want to bring all tax amount to MM

pricing procedure, then create a new condition type ( M/06), have Cond. Class:

D, Calculate. type: B and Cond.category: N and in it and add new condition type

in MM pricing procedure. When you create a PO with excise taxes , all tax

amount flow to new condition type in MM pricing procedure.

Concept of tax code and tax calculation: You

need to enter plant during PO creation and in plant you have country code in t.

code: OX10 and then country code assigned to tax procedure in t. code: OBBG

which in turn Tax Procedure triggers by entering a tax code in PO.Its practical

unless tax code assigned to company code, the tax amount never appears in tax

segment in PO.

You need to

customize (M/06) a new condition type as ZTAX where you can have all tax value

that will flow from Tax procedure to MM pricing procedure. You can have

following parameter for customize a condition type ZTAX

Cond. Class: D

Calculat.type: B

Cond.category: N

& keep BLANK

access sequence filed & make it as item condition and then add this

condition type in MM pricing procedure (M/08) with a logic just before

calculation of TOTAL price.

Now do create PO

with all taxes and now you can all tax amount in condition type ZTAX in PO

Condition TAB( which flow from tax procedure to MM pricing procedure with

customize a condition type ZTAX)

NOTE:

If you do not want

to use customized condition type ZTAX, then try to use NAVS condition type in

pricing procedure (M/08)with logic just before calculation of TOTAL price .

In procurement of material/service, the tax components

involved where it have two

pricing procedures, one is MM

pricing procedure(M/08) & another one is Tax

procedure(OBYZ).These

two procedure linked by a tax code in the purchase order which need to be

entered in the must.

But in sales ONLY ONE which is SD

pricing procedure for SD Pricing

& TAX calculation are used where it includes all tax components with

material price.

Question:- I want to Know the link Between Tax Procedure and

Pricing Procedure in CIN. When entering Order which How Tax condtypes

reflected.

Answer:-TAXINJ- All tax calculations MM & SD side are calculated in Taxprocedure. SD pricing procedure copies the tax calculation from Taxprocedure to SD condition types in pricing. Deductable & Non deductable calculated in MM Side calculated in Tax procedure. SD & MM condition types maintained in taxprocedure. Here taxcode maintained in FTXP links tax procedure & pricing procedure. UTXJ is the condition type which connects both

Thursday, 25 March 2021

Batch Management complete configuration in MM, PP & SD module

Functional Usage:-

This functionality is activated in SAP based on the business requirement that products produced and procured need to be identified separately for tracking purposes. Food industries, pharmaceuticals, and chemical industries are a good example where Batch Management needs to be maintained. Tracking a material with a unique Batch number involves several functions in SAP:

- Inventory Management (IM) – To search Batch numbers during material movement into the plant

- Production/Process Order (PO) – To search Batch stock for components when creating/releasing PO

- Sales and Distribution (SD) – Search for Batch during Sales Order processing.

- Warehouse Management (WM) – To search specific Batch for a Warehouse.

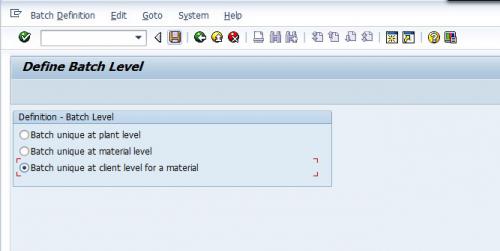

Batch Management Level

There are three different levels for Bath Management:

Plant Level

At a plant level, a Batch number is unique for a material inside a plant only. The same Batch number can be generated at another plant under the same Company, though these Batches are not the same. If a plant-to-plant stock transfer scenario is used, plant-level Batch numbering is not suitable.

Client Level

In this case, the Batch number is unique for the entire Client, meaning the same Batch number will not be generated for different Plants under the same Company Code. This method is useful when plant-to-plant stock transfer is used, and the Batch number is supposed to be unique.

Material Level

With this method, the Batch number will be unique at the material level only. Thus, in a given plant, different materials can have the same Batch number.

Batch Specifications Master Data Structure

Creation of Characteristics

Characteristics can have a fixed value, number range, or can pull values from SAP tables directly. For example, the production date of manufacturing of a produced goods can be found from production order table data, and manual intervention is not required.

During characteristics creation (Tcode CT04), we define how characteristics values will be maintained. Also, characteristics values can be blank so that it can be maintained at a material master classification view later on.

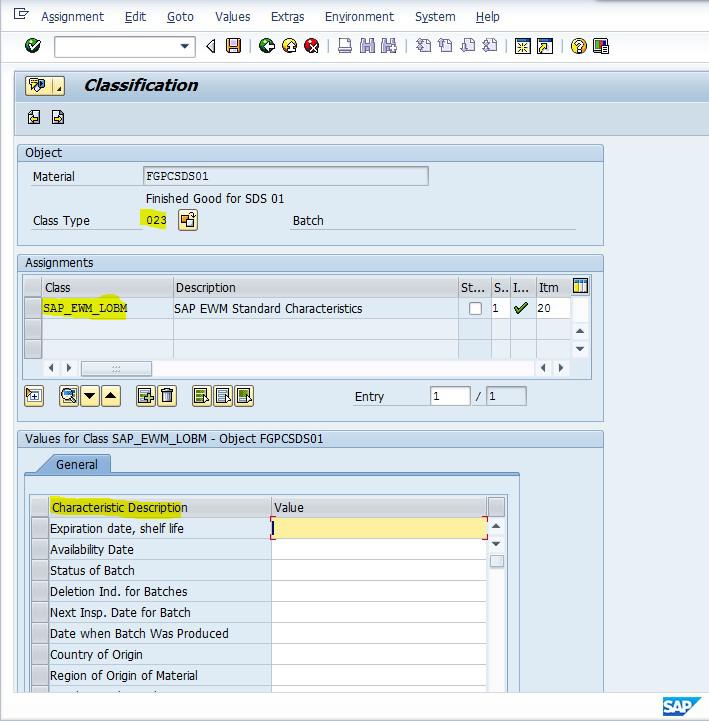

Creation of Class

All required characteristics are assigned into a Class (Tcode CL01) with class type 023 (Batch Class). In the figure above, ‘SAP_EWM_LOBM’ is the required class that holds all relevant characteristics.

Material Master Maintenance

Finally, the class with assigned characteristics is maintained in the material master classification view (Tcode MM01/MM02). Also, the Batch Management box is ticked in the material master view.

Define Batch Determination

Automatic Batch Determination is used in Inventory Management, Production, Sales & Distribution, and Warehouse Management. It is used to select batches and allocate them in a manufacturing order, an outbound delivery, or a goods issue/good receipt/goods transfer in Inventory Management.

In Production, Sales & Distribution, Inventory Management, or Warehouse Management, the batch determination is used to search and allocate batches for the components in production/process orders. Alternatively, batch determination is used to search and allocate the delivery batches in a customer-based outbound delivery or to search and allocate batches in goods issues.

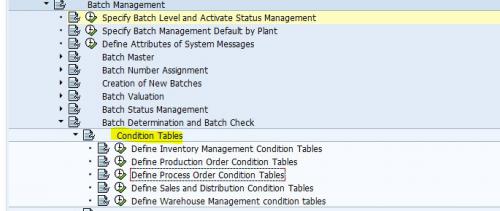

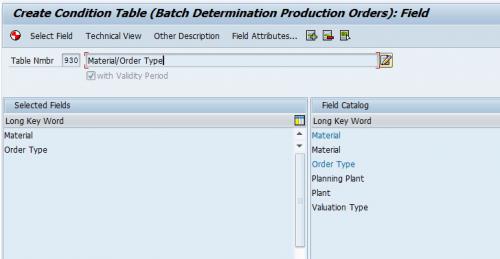

Create Batch Determination Condition Technique

Once Batch determination condition tables have been created, they become the key combination fields for searching batches. Eventually, the condition records or search strategies are created as master data based on these key combinations. The Condition Tables are created separately for IM, Production, WM, and Sales.

Different Menu Path for IM, PO, SD, and WM Relevant Condition Table

Fig. 4: Batch Condition Table for Production Order

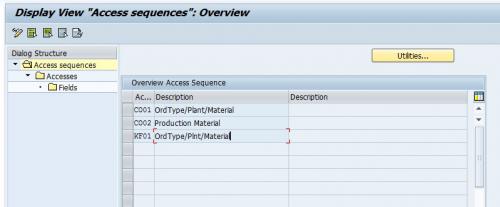

Create Batch Determination Access Sequence

Batch determination access sequences have multiple condition tables (key combinations) assigned in a sequence of priority. This facility allows you to create data for many key combinations so that even if the batch search fails on the first key combination condition, the rest in the priority will help in the search. The Access Sequences are created separately for IM, Production, WM, and Sales. The below screenshot shows all the screens involved in the access sequence configuration.

Batch Access Sequence

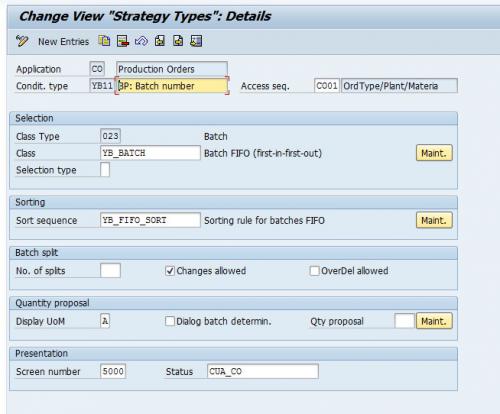

Create Batch Strategy Types

A Batch Search Strategy contains multiple access sequences, though not assigned in any sequential priority. The assignment of the strategy types is done separately for IM, Production, WM, and Sales. The strategy types or condition types are assigned in priority in the next step called “Batch Search Procedure Definition.”

A Batch search strategy is used to search batches using specific rules because you want to automate the process and do not want it to do it manually for every Batch. Thus, you have to aid the system in putting in a decision such as - search all the batches of a given plant, search all batches of a given set of materials within a plant, or search batches for a given component.

Batch Strategy Types

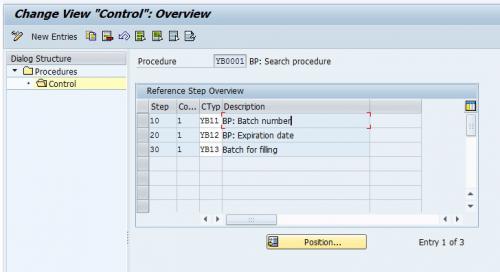

Create Batch Search Procedure

A Batch Search procedure contains multiple strategy types assigned in sequential priority. The Batch search procedure thus becomes the final configuration, which includes the total search configuration together. As before, the Batch Search Procedures are created separately for IM, Production, WM, and Sales.

Batch Search Procedure

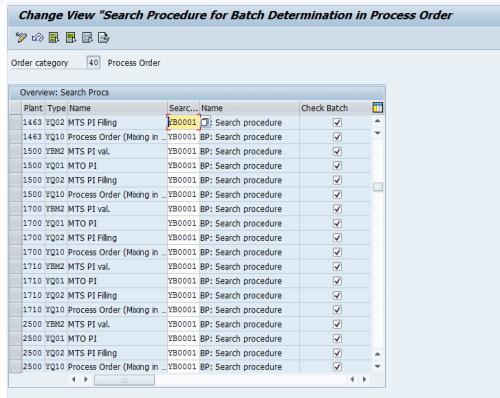

Batch Search Procedure Allocation and Check Activation

In this step, we allocate the batch search procedure to the respective modules. In the case of Inventory Management, the Batch search procedures are assigned to the Movement types. In the case of Production or process orders, the batch search procedures are attached to the production plants and order types.

For the Sales & Distribution module, the Batch Search Procedures are assigned to the Sales Areas and Sales document type. And finally, for Warehouse Management, the Batch Search procedures are attached to the Warehouse number and can also be assigned to the warehouse number + Movement type combination.

Production/Process Order Batch search procedure allocation via plants and order types

After completing the entire configuration, the Batch search condition record can be generated using these SAP transaction codes:

- For Inventory Management: MBC1 – Create, MBC2 – Change, MBC3 – Display

- For Production Order/Process Order: COB1 – Create, COB2 – Change, COB3 – Display

- For Sales & Distribution: VCH1 – Create, VCH2 – Change, VCH3 – Display

- For Warehouse Management: LS51 – Create, LS52 – Change, LS53 – Display.

New changes in Batch Management in S/4 HANA 1809 ( Interview Q & A )

SAP has given a new field in material master to activate the batch management for the required plant only.

New configuration is provided to enable or disable this settings in OCHA. Batch level will activated at material level for the required plant, however if it required to deactivate the settings, selected plant can be deactivated so that inventory will not be at batch level.

Take a test.

Transfer a batch stock from MPRL plant (Batch Managed) to PL01( Non natch managed). However, Material is activated as batch managed.

Conduct Stock transfer between 2 plants either by STO or by 2 step stock transfer(303, 305).

Stock is transferred from MRPL to PL01 without batch.

This functionality will definitely enhance the business requirement to keep batch stock in one plant and without batch in another if multiple plants operate in stock transfer scenarios like production plant and distribution plants

Wednesday, 24 March 2021

Business Partner Complete Configuration in S/4 HANA 1709

Creation of a

Business Partner:-

1.1 Define BP Roles

|

Path |

|

|

T- Code |

NA |

|

BP

Roles |

Title |

Description |

|

FLCU00 |

FI

Customer |

Business

Partner FI Customer |

|

FLCU01 |

Customer

Sales |

Business

Partner Customer Sales |

|

FLVN00 |

FI

Vendor |

Business

Partner Vendor FI |

|

FLVN01 |

Vendor

Purchase |

Business

Partner Vendor Purchase |

Process:-

·

Standard BP Roles will be used

·

Rename the Role

·

Save it.

1.2 Define Number Ranges

|

Path |

|

|

T- Code |

|

|

No. |

From No. |

To No. |

External Assignment |

|

|

|

|

|

|

K1 |

2xxxxxx |

2xxxxxx |

|

|

K2 |

2 |

2 |

|

|

K3 |

2 |

2 |

|

|

K4 |

2 |

2 |

|

|

K5 |

2 |

2 |

|

|

K6 |

2 |

2 |

|

|

K7 |

2 |

2 |

|

|

K8 |

2 |

2 |

|

|

K9 |

2 |

2 |

Tick |

|

D1 |

1 |

1 |

|

|

D2 |

1 |

1 |

|

|

D3 |

1 |

1 |

|

|

D4 |

1 |

1 |

|

|

D5 |

1 |

1 |

|

|

D7 |

1 |

1 |

|

|

D9 |

1 |

1 |

Tick |

Process:-

·

Click on Intervals

·

Maintain the Number Ranges for BP,

Customer and Vendors

·

Save it.

1.3 Define Groupings and Assign Number Ranges

|

Path |

|

|

T- Code |

NA |

|

Grouping |

Short

Name |

Description |

Number Range |

|

|

|

|

|

|

|

|

AK10 |

Domestic

Vendors |

Domestic

Vendors |

K1 |

|

|

AK20 |

Transport Vendors |

Transport Vendors |

K2 |

|

|

AK30 |

Service Vendors |

Service Vendors |

K3 |

|

|

AK40 |

Import Vendors |

Import Vendors |

K4 |

|

|

AK50 |

FI Vendor |

FI Vendor |

K5 |

|

|

AK60 |

Sub Contract Vendor |

Sub Contract Vendor |

K6 |

|

|

AK70 |

One Time Vendor |

One Time Vendor |

K7 |

|

|

AK80 |

AsianLak Employees |

AsianLak Employees |

K8 |

|

|

AK90 |

STO Plant as Vendor |

STO Plant as Vendor |

K9 |

|

|

AD10 |

CUST – Distributor |

CUST – Distributor |

D1 |

|

|

AD20 |

CUST - Modern Trade |

CUST - Modern Trade |

D2 |

|

|

AD30 |

CUST – Retail |

CUST – Retail |

D3 |

|

|

AD40 |

CUST – Export |

CUST – Export |

D4 |

|

|

AD70 |

One Time Customer |

One Time Customer |

D7 |

|

|

AD90 |

STO Plant as Customer |

STO Plant as Customer |

D9 |

|

|

|

|

|||

Process:-

·

Click on New Entries

·

Maintain the BP Groupings , Short

Name, Description and Number Range

·

Save it.

1.4 PPO Activation

|

Path |

|

|

T- Code |

NA |

Process:-

·

Put Tick on PPO Active against

Syn. Object

·

Save it.

1.5 Activate Synchronizations Options

|

Path |

|

|

T- Code |

NA |

|

Source

Object |

Target

Object |

Act.

Ind. |

|

BP |

CUSTOMER |

Put

Tick On |

|

BP |

VENDOR |

Put

Tick On |

|

CUSTOMER |

BP |

Put

Tick On |

|

VENDOR |

BP |

Put

Tick On |

Process:-

·

Click on New Entries

·

Select the Source Object and

Target Object and Activate the Indicator by putting Tick on

·

Save it.

1.6 Set BP Role Category for Customer Integration

|

Path |

|

|

T- Code |

NA |

|

Role

Category |

Description |

|

FLCU00 |

Business

Partner FI Customer (FS: BP) |

|

FLCU01 |

Business

Partner Customer (FS: BP) |

Process:-

·

Standard Roles

1.7 Define BP Role for Direct Customer to BP

|

Path |

|

|

T- Code |

NA |

|

Group |

BP

Role |

|

ZD10 |

FLCU01 |

|

ZD20 |

FLCU01 |

|

ZD30 |

FLCU01 |

|

ZD40 |

FLCU01 |

|

ZD70 |

FLCU01 |

|

ZD90 |

FLCU01 |

Process:-

·

Click on New Entries

·

Select Group and Maintain BP Role

·

Save It.

1.8 Define Number Assignment for

Direction BP to Customer

|

Path |

|

|

T- Code |

|

|

Grouping |

Short

Name |

Account

Group |

Name |

Same

Numbers |

|

AD10 |

CUST –

Distributor |

ZD10 |

CUST –

Distributor |

Put Tick |

|

AD20 |

CUST

- Modern Trade |

ZD20 |

CUST

- Modern Trade |

Put Tick |

|

AD30 |

CUST

– Retail |

ZD30 |

CUST

– Retail |

Put Tick |

|

AD40 |

CUST

– Export |

ZD40 |

CUST

– Export |

Put Tick |

|

AD70 |

One

Time Customer |

ZD70 |

One

Time Customer |

Put Tick |

|

AD90 |

STO

Plant as Customer |

ZD90 |

STO

Plant as Customer |

Put Tick |

Process:-

·

Click on New Entries

·

Select Grouping and Account Group

·

Put Tick on Same number

·

Save It

1.9 Set BP Role Category for Vendor Integration

|

Path |

|

|

T- Code |

|

|

Role

Category |

Description |

|

FLVN00 |

Business

Partner FI Vendor (FS: BP) |

|

FLVN01 |

Business

Partner Vendor (FS: BP) |

Process:-

·

Standard Roles

1.10 Define BP Role for Direct Vendor to BP

|

Path |

|

|

T- Code |

NA |

|

Group |

BP Role |

|

YK10 |

FLVN01 |

|

YK20 |

FLVN01 |

|

YK30 |

FLVN01 |

|

YK40 |

FLVN01 |

|

YK50 |

FLVN00 |

|

YK60 |

FLVN01 |

|

YK70 |

FLVN01 |

|

YK80 |

FLVN00 |

|

YK90 |

FLVN01 |

Process:-

·

Click on New Entries

·

Select Group and Maintain BP Role

·

Save It

1.11 Define Number Assignment for Direction BP to Vendor

|

Path |

|

|

T- Code |

|

|

Grouping |

Short Name |

Account Group |

Name |

Same Numbers |

|

YK10 |

Domestic Vendors |

ZK10 |

Domestic Vendors |

Put Tick |

|

YK20 |

Transport

Vendors |

ZK20 |

Transport

Vendors |

Put Tick |

|

YK30 |

Service

Vendors |

ZK30 |

Service

Vendors |

Put Tick |

|

YK40 |

Import

Vendors |

ZK40 |

Import

Vendors |

Put Tick |

|

YK50 |

FI

Vendor |

ZK50 |

FI

Vendor |

Put Tick |

|

YK60 |

Sub Contract

Vendor |

ZK60 |

Sub Contract

Vendor |

Put Tick |

|

YK70 |

One

Time Vendor |

ZK70 |

One

Time Vendor |

Put Tick |

|

YK80 |

AsianLak

Employees |

ZK80 |

AsianLak

Employees |

Put Tick |

|

YK90 |

STO

Plant as Vendor |

ZK90 |

STO

Plant as Vendor |

Put Tick |

Process:-

·

Click on New Entries

·

Select Grouping and Account Group

·

Put Tick on Same number

·

Save It.

Best Q & A for Interview

Closed MM period reopened in SAP MM

Sometimes, the Client requirement comes to reopen the MM closed period which is not possible directly through the MMPV t-code but We have on...

100% Success Factor

-

Subcontracting Process in GST: India. Concept of Subcontracting process:- Subcontracting is a process of providing components/goods to ven...

-

SAP ECC Vs SAP S/4 HANA ( MM point of View ):- There some Major changes in SAP S/4 HANA. Material code Length is increased from 18 to 40 d...

-

Functional Usage:- This functionality is activated in SAP based on the business requirement that products produced and procured need to be i...